Plasma activation - Surface activation with plasma

Enhancing the quality and durability of coatings and bonded joints.

What is plasma activation?

Plasma activation enhances the durability and quality of coatings and paints as well as improving the strength of joints bonded with adhesives.

Many high-performance plastics such as POM PTFE and PP etc. are nonpolar hence difficult to adequately wet with adhesive or paints.

How does plasma activation work?

Low pressure plasma provides a controlled environment which is sterile and dry. The plasma envelopes the complete surface to be treated penetrating even the smallest of fissures.

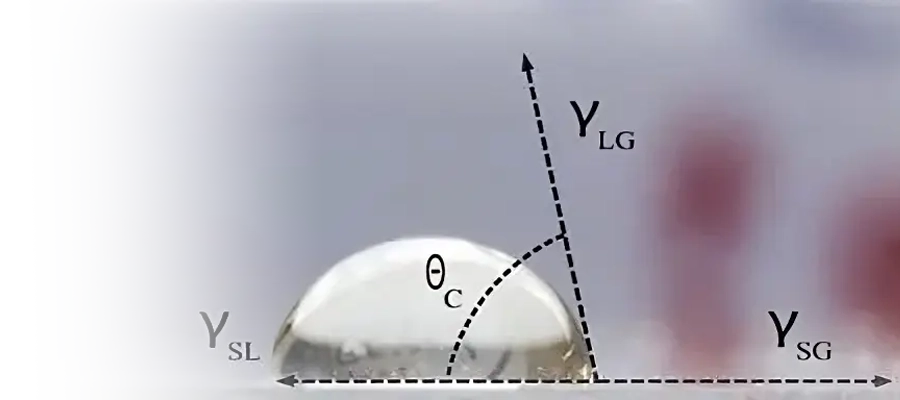

During plasma activation functional groups are formed as bonds are broken in the surface molecules by the highly energetic plasma. These functional groups are now available to bond with the coating material.

Combined process to maximize the effect and life of the activation

Often plasma activation is performed after plasma cleaning and possibly etching ensuring the best possible contact between the materials with a maximal area.

It may be followed by priming the surface to further improve bond strength or adhesion of coatings or paints and to extend the storage life of the activated surface. Improving adhesion

All the stages can be carried out with a single process in the plasma chamber, providing an extremely economic alternative to methods carried out in atmospheric conditions or using wet agents. As the process gas used can be air enriched with oxygen it is also environmentally friendly.

The geometry of the parts that can be treated is almost limitless from find powders and bulk gods up to roll goods and larger individual parts.

Is plasma activation effective on all materials?

Plasma activation is not just limited to plastics, the surfaces of glass, wood, and metal for example can all be activated with plasma.

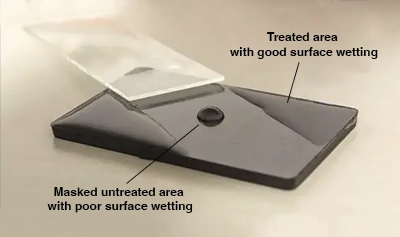

Image shows the improved surface contact (wetting) of in this case water with the treated areas of the sample. The droplet in the center of the untreated area resists spreading over the surface.