Questions

Requirements for good bond strength - Paint adhesion

- Compatibility between the adhesive and the surface of the work piece.

- Maximal area of intimate contact between the surfaces of the work piece and the adhesive or paint.

- To achieve all this with minimal or no damage to the surface plasma bonding/painting preparation is an excellent option. It offers a one-step safe and environmentally friendly controlled process for complex parts or bulk goods.

Advantages plasma processing can offer

Q and A about using Plasma to improve adhesion and bonding.

How can low pressure Plasma reduce costs?

Small area footprint. One plasma system can complete the stages needed to prepare for painting or bonding. Saving floor space.

Efficiency. Multiple consecutive processes are possible without removing the product. One or thousands of items can be processed at the same time.

Our plasma processors can be programmed to complete:-- Cleaning

- Etching

- Priming

With a single loading.

Low maintenance costs

No waste disposal costs.

Learn more about cost effective

or small

Is the process repeatable?

Yes.

- The process is programmable and recorded.

- The process is in an enclosed controlled environment.

- The small amounts of process gas used are always fresh.

Is the process environmentally friendly?

Yes.

- The process is both safe and environmentally friendly.

- The process gas is used in very small amounts. Especially when compared to Atmospheric plasma.

- No aggressive fluids or hazardous waste. It is a dry process.

- No problems with Ozone.

Which process steps can be completed in a single loading?

Any combination of:

- cleaning More information about plasma cleaning

- Etching More information about plasma etching

- Priming

You only need to touch the parts once. The process can be programmed to clean, etch, and prime. With no interruptions, with each step of the process being recorded for quality assurance.

The different process gases are connected to the chamber and automatically selected as needed.

What quality control tests are used for paint adhesion?

Cross cut test

Standard test for determining the adhesion of paint to a substrate as detailed in DIN EN ISO 2409 or ASTM D3359-02.

LABS test

A Germany term for paint repelling surface test. Often referred to as the orange peel effect.

English translation: Paint-Wetting Impairment Substances (PWIS)

What quality control tests are used for bond strength?

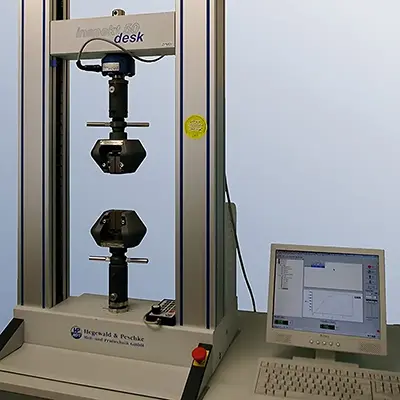

Tensile strength tester and Microscope

The load required to break the bond or peel paint can be measured.

After destructive testing the breakage pattern of the bond can be evaluated. To observe if the breakage was cohesive or adhesive for example.