Support - Service overview

Our service encompasses the process and system development, system manufacturing, support and maintenance of your plasma system. We can also offer in house treatment of your parts and material.

Analysis of the Problem - need

What is the objective?

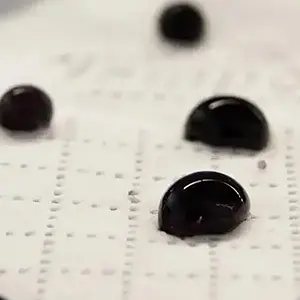

Which materials and parts need to be treated? Either bonded, cleaned, coated or painted?

Which adhesive or paint system will be used?

Other needs?

Plasma process development

Risk analysis

Manufacture

CE. Certification

Commissioning

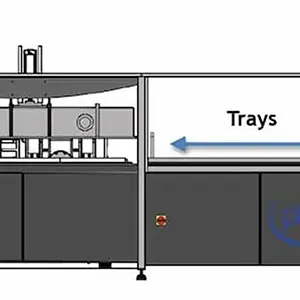

Plasma system concept development

Integration of the plasma system into existing production line.

Optimizing the plasma process

Process cycle time optimization

System development and manufacture

Which plasma process is best suited?

Process development by treating and testing samples

Test the process at the customers if possible,

or with a rental system

Training and demonstration

Delivery and commissioning

Installation and connection of the plasma system

Initial commissioning

Training of employees

FAT and final acceptance now also possible online

New circumstances require new approaches.

In the past few months, due to increased demand from our customers, we have been able to gain very positive experience with factory and final acceptance tests online. In addition, it was possible to participate in process trainings with larger groups from different locations. Thus, there is the possibility to be connected live to our experts on site. Question and answer rounds can be easily realized this way.

In addition, with the consent of all participants, the event can be recorded and used for later training purposes. You thus save (travel) time and expenses, as well as protecting the environment and the health of your employees. In addition, participants from all over the world can join in and repeat the event at a later, flexible date. Connected together in times of creativity.